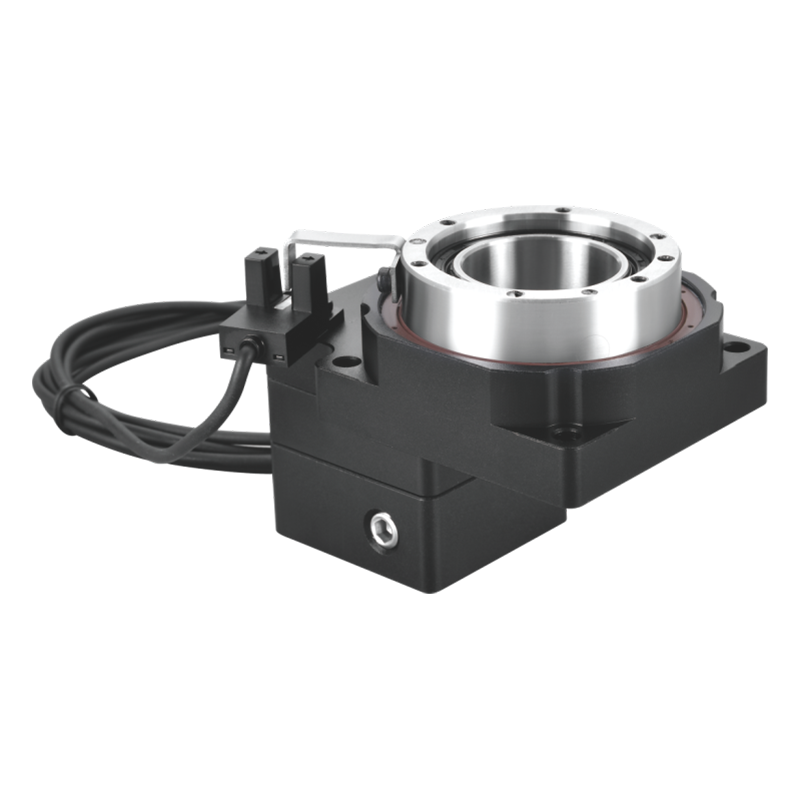

In the previous article, we introduced the difference between the hollow rotating platform and the cam divider. Now we will focus on the accuracy requirements and installation essentials of the hollow rotating platform reducer.

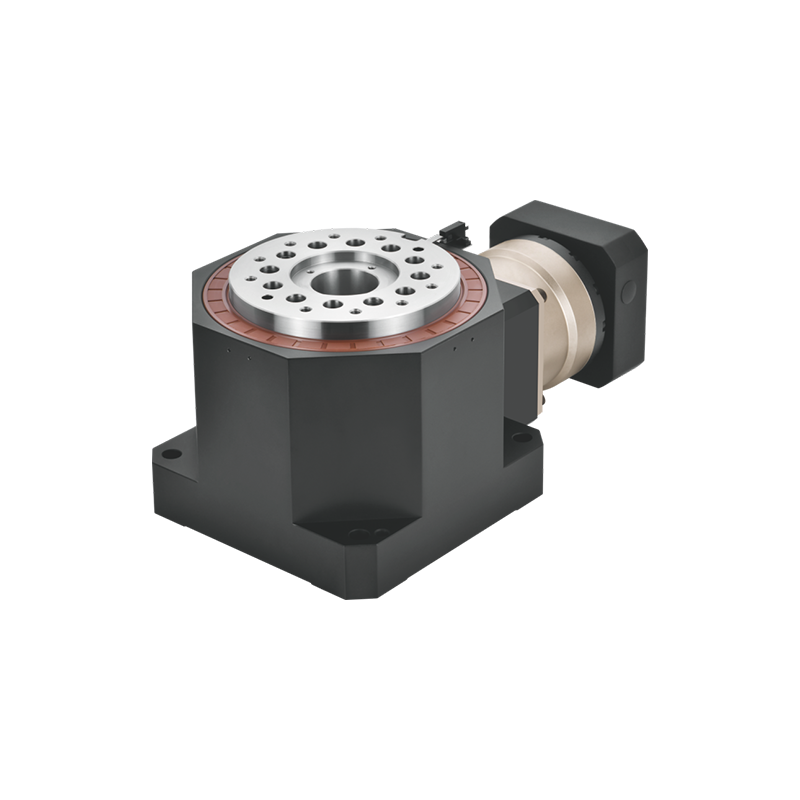

Precision of hollow rotating platform reducer

The accuracy of the hollow rotating platform reducer depends on various factors, including manufacturing and assembly accuracy, raw material product quality, rolling bearing selection and working environment, etc. Among them, manufacturing and assembly accuracy are one of the important factors that determine the accuracy of the hollow rotating platform. For example, if there are deviations during the manufacturing and assembly process, the accuracy index values such as axis runout, coaxiality, and parallelism of the hollow rotating platform may not meet the standards. The quality of raw material products is also one of the factors that affects accuracy. High-quality raw materials can ensure the hardness and stable performance of the hollow rotating platform, thereby improving accuracy. In addition, the selection of rolling bearings and the working environment will also affect the accuracy of the hollow rotating platform.

Under normal circumstances, the repeated positioning accuracy of the hollow rotating platform reducer can reach less than 5 arc seconds, which has exceeded the accuracy of traditional motor bearings. However, the actual accuracy index value needs to be evaluated based on the specific model and application environment. In order to ensure the accuracy of the hollow rotating platform reducer, it is recommended to choose well-known brands and quality-assured products when purchasing, and at the same time pay attention to maintenance and care during use.

Installation process of Zhuoerchuang hollow rotating platform reducer:

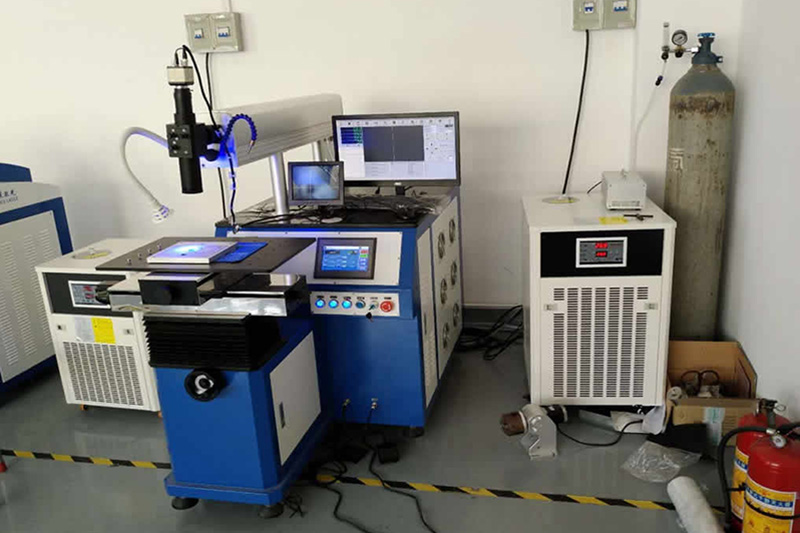

1. Make sure that the motor and the hollow rotating platform reducer are intact, and strictly check whether the dimensions of the connecting parts between the motor and the reducer match.

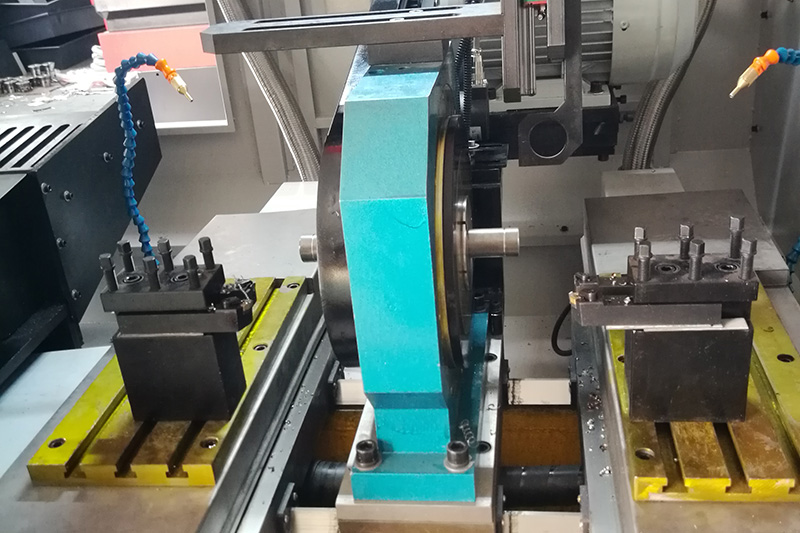

2. Clear the installation environment to ensure it is flat and clean to facilitate accurate assembly of the hollow rotating platform.

3. According to the design standards and installation manual, determine the position of the hollow rotating platform reducer, and use bolts, clamps or clamping devices to firmly fix it at the required position.

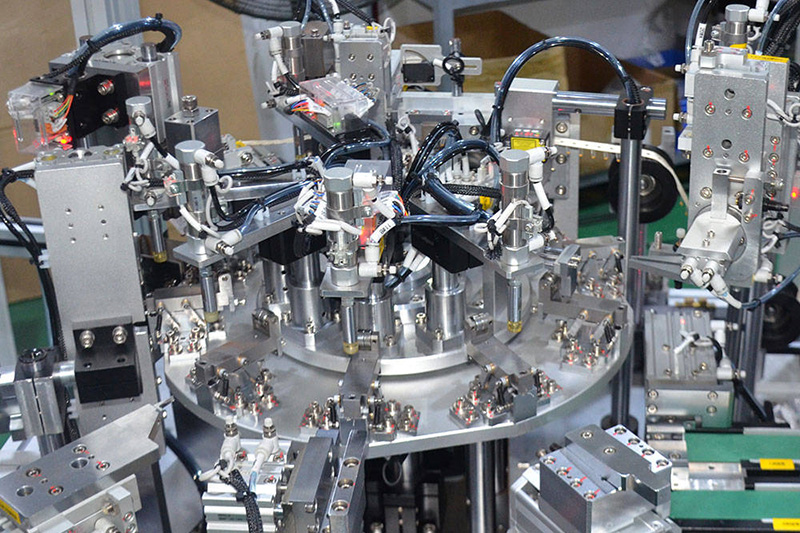

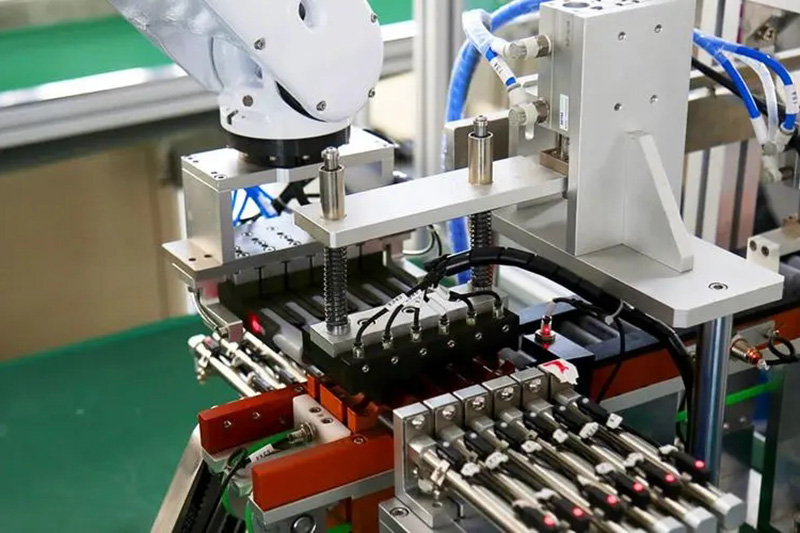

4. Connect the transportation channels of the hollow rotating platform, such as gas, liquid, cable or optical fiber, and perform necessary calibration and verification.

5. During installation, it is strictly forbidden to hit with a hammer to prevent excessive axial or radial force from damaging the bearings or gears. Be sure to tighten the mounting bolts before tightening the force bolts.

6. Before installation, wipe the anti-rust oil on the motor input shaft, positioning boss and hollow rotating platform reducer connection parts with gasoline or zinc-sodium water. Its purpose is to ensure the tightness of the connection and the flexibility of operation, and to prevent unnecessary wear and tear.