Description

——

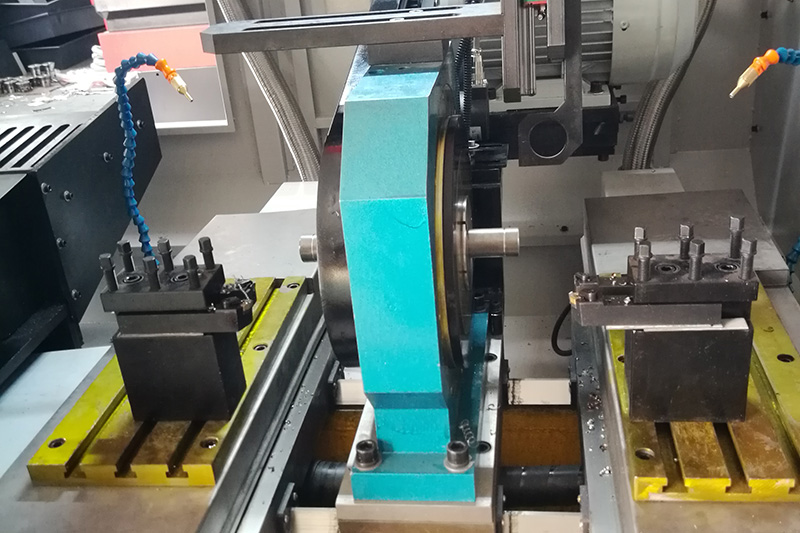

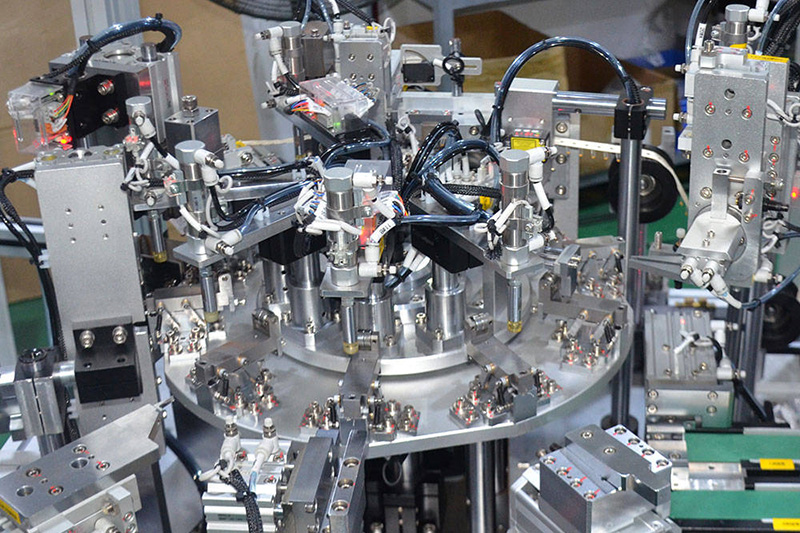

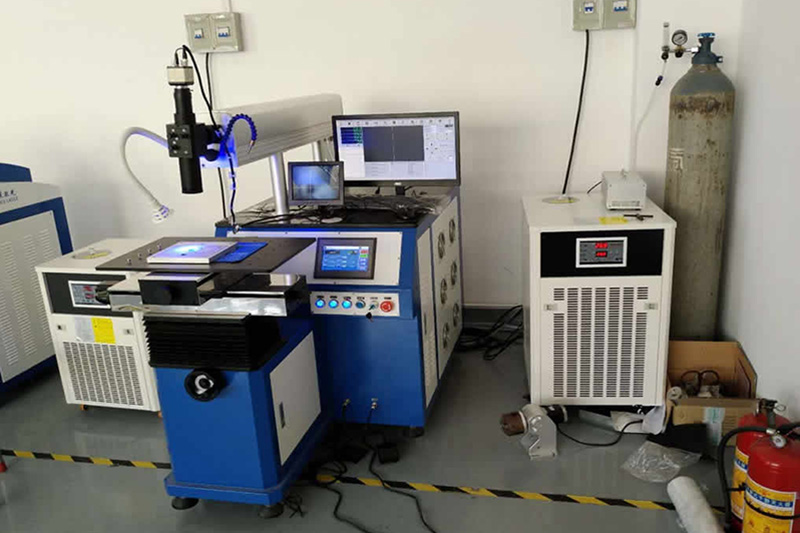

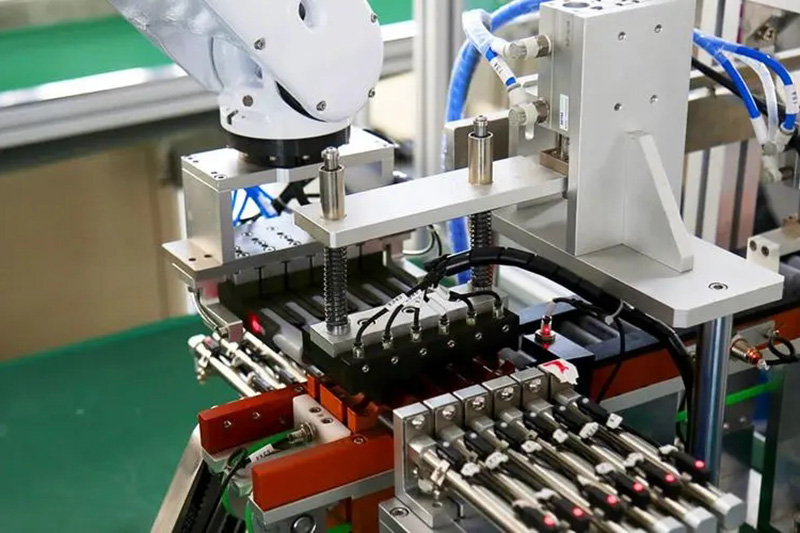

Printing equipment is mainly the process of transferring graphics and text to paper, leather, PVC, textiles and plastic products through the control system of the printing machine. The flexibility is very strong, as long as the layout of the original manuscript is prepared, ink adjustment, printing and other processes will be fine.

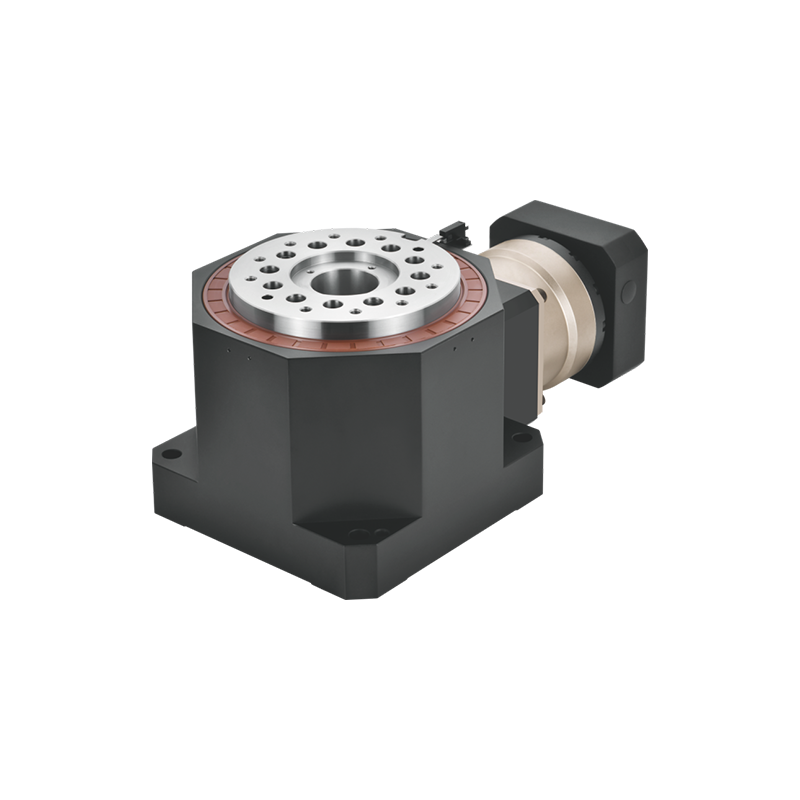

Generally, printing equipment requires high precision and high-efficiency synchronization performance in the case of high-speed operation. The key lies in the fact that the internal precision structure of the hollow rotary platform is a gear structure. Using double gears for rotation, the rotation accuracy is relatively high, and the torque is relatively large. .

Advantages

——

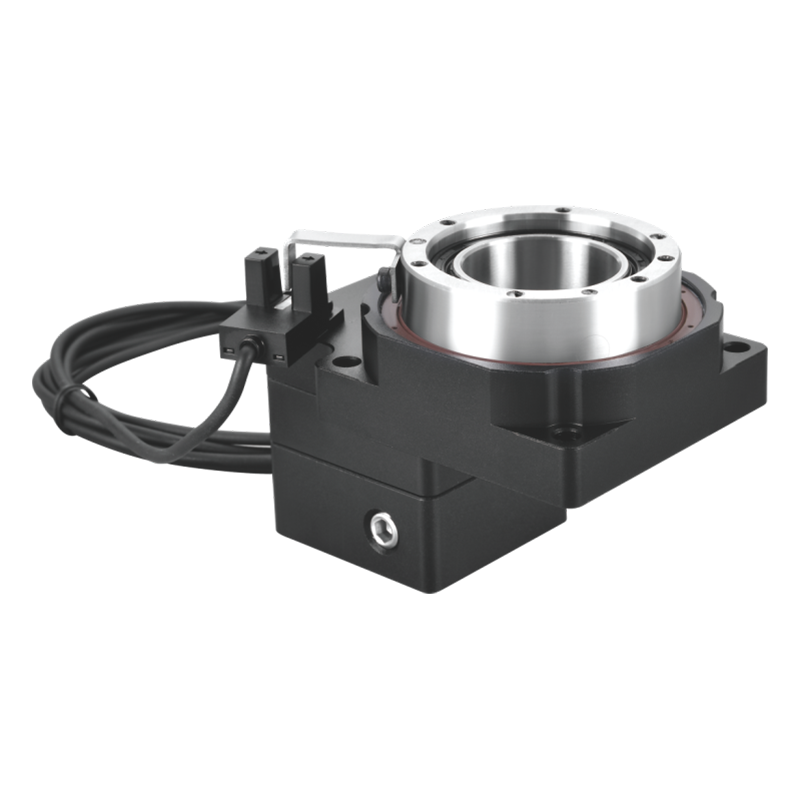

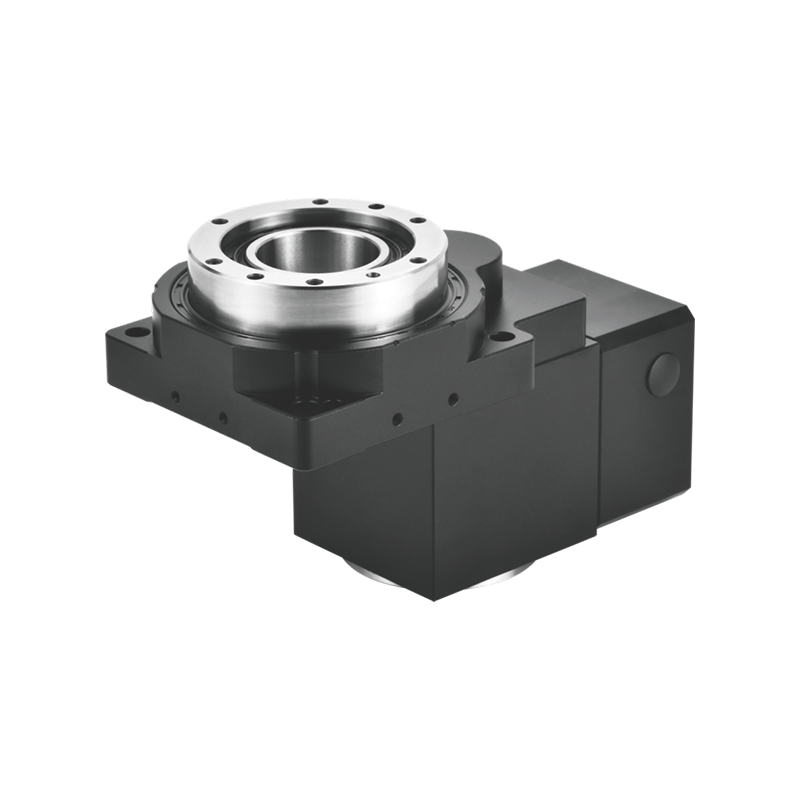

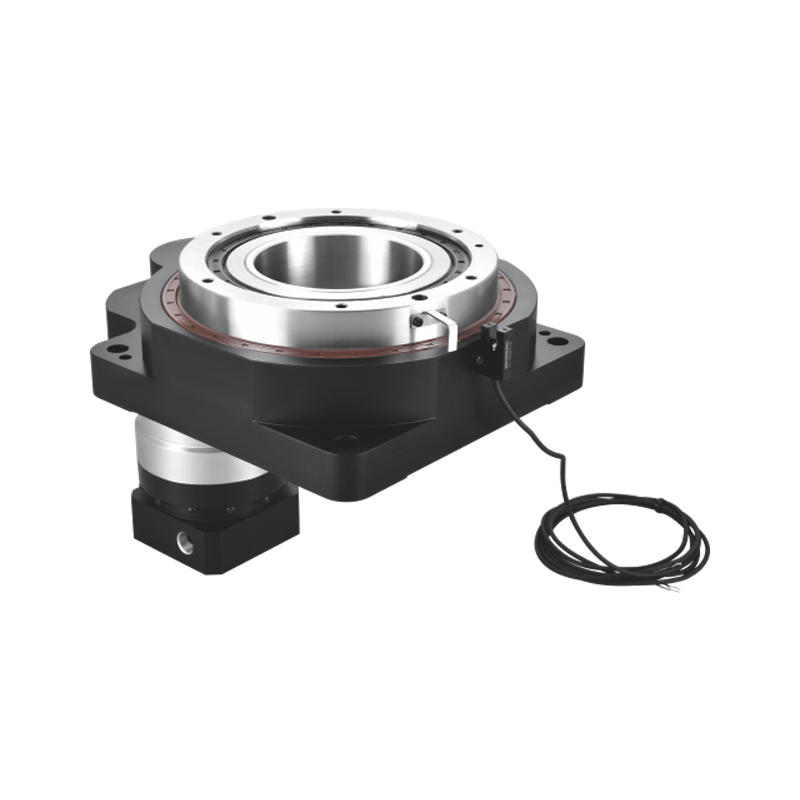

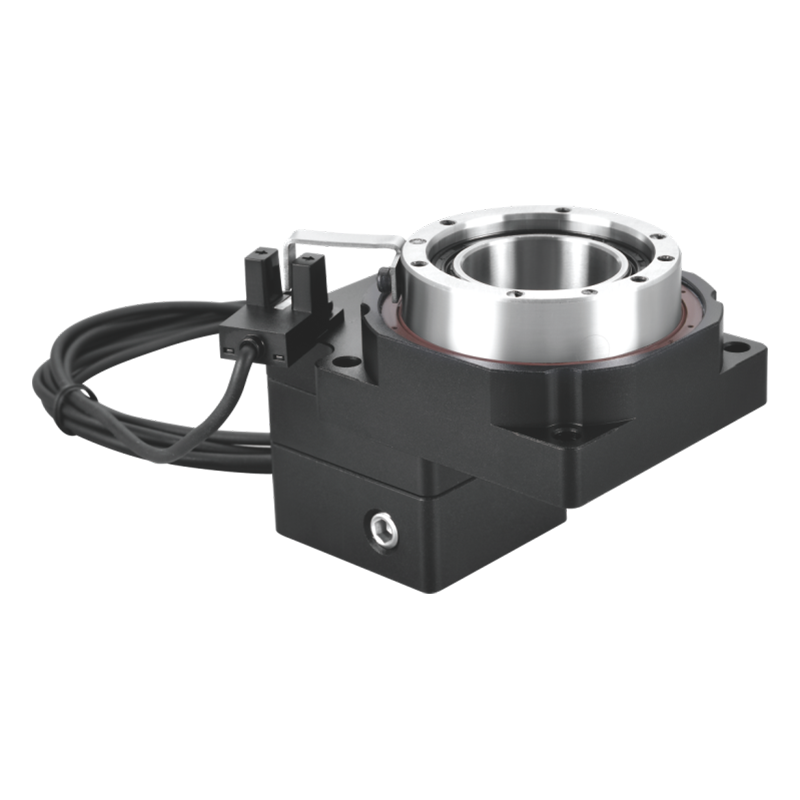

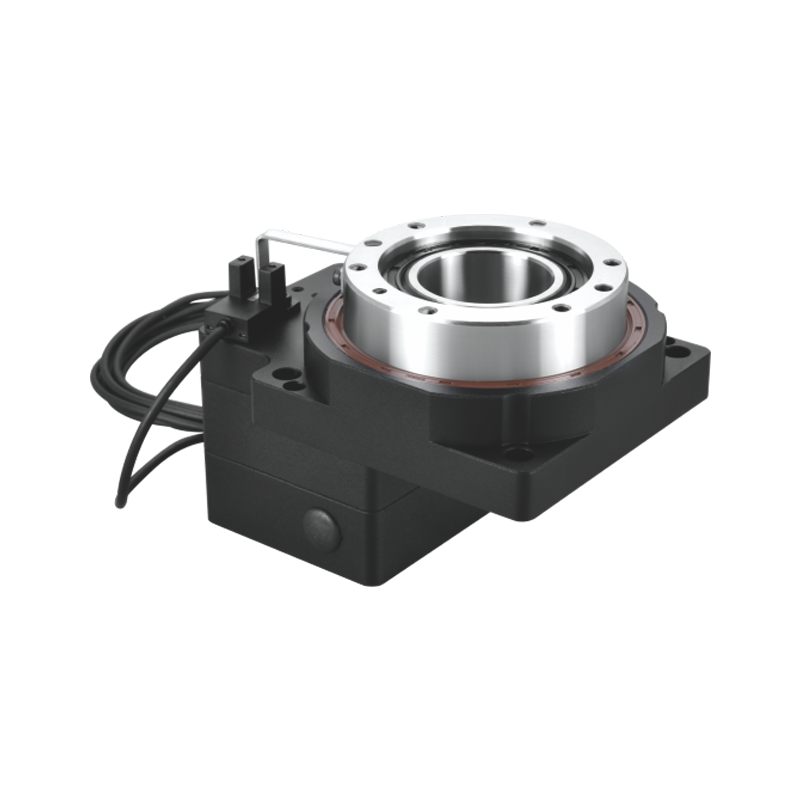

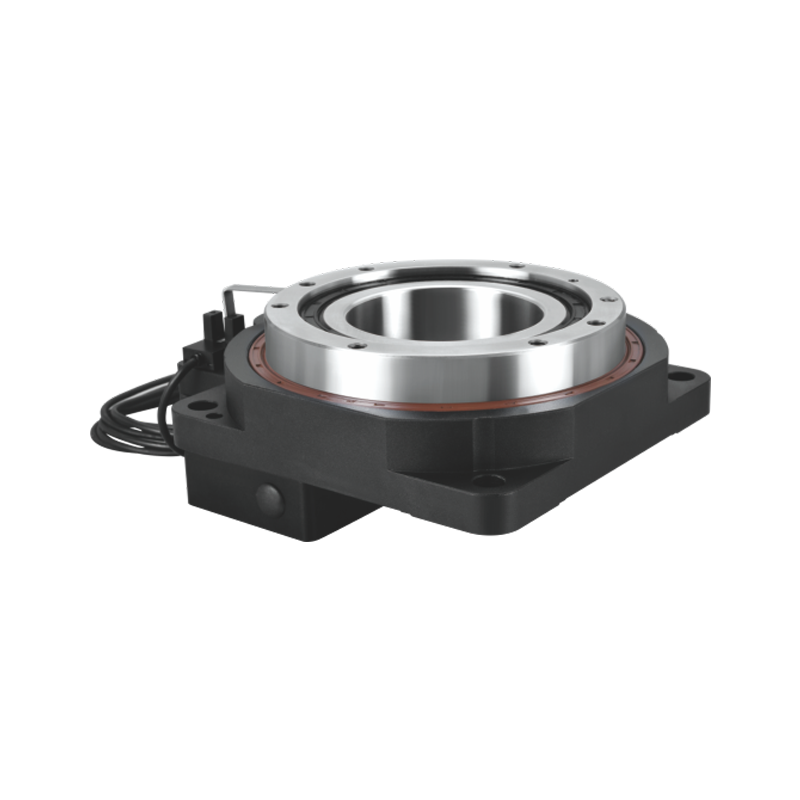

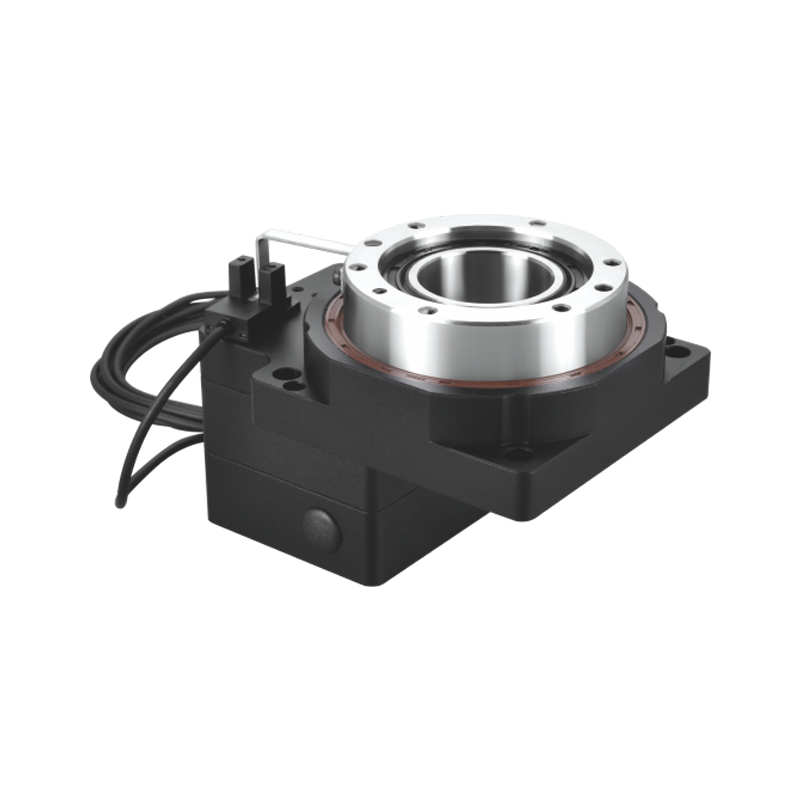

Crossed roller bearings: The main supporting function inside the hollow rotating platform is the crossed roller bearings. The inner bearing rollers are vertically staggered, with the diameter of the crossed rollers being slightly larger than the diameter of the raceway between the inner and outer rings of the roller bearing. The purpose of using crossed roller bearings is to endow the hollow rotating platform with the ability to withstand moments in multiple directions including axial and radial.

High synchronization performance: It can be matched with any 100-750W servo motor, and it can be directly locked when working, locking the workpiece, and improving the convenience of loading.

Large torque: In order to increase the output torque, the gear precision grade is required to be lower than grade 5. In addition, the flexible gap adjustment mechanism controls the gap by changing the center distance of the two gears, so that the idling of the hollow rotary platform is minimized, and the repeat positioning accuracy is less than 5 arc seconds

Related Products

——

ZCT62 Hollow Rotating Platform | ZCT85 Hollow Rotating Platform | ZCT130 Hollow Rotating Platform | ZCT200 Hollow Rotating Platform |