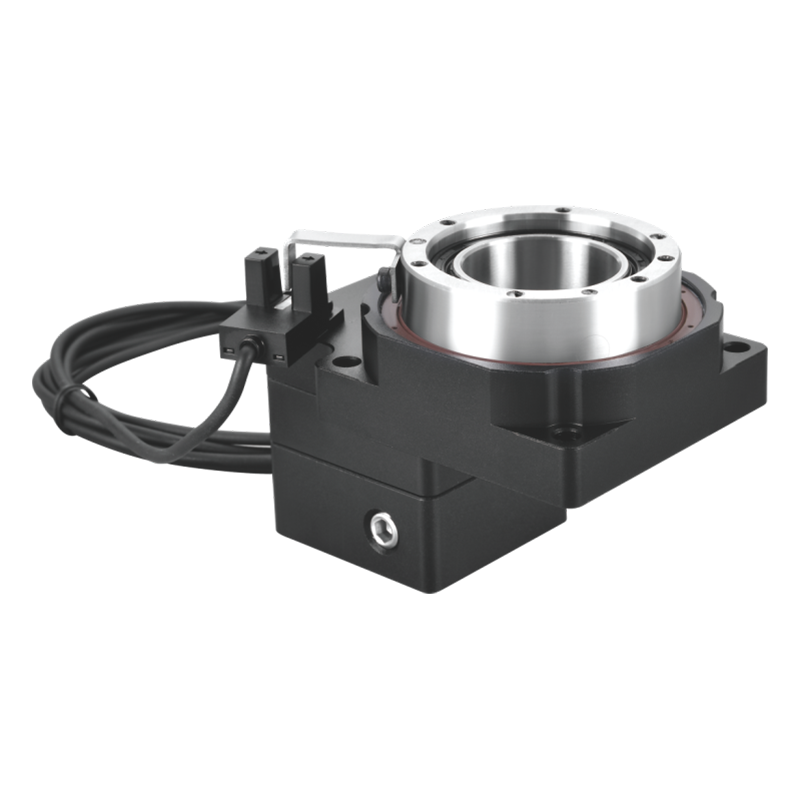

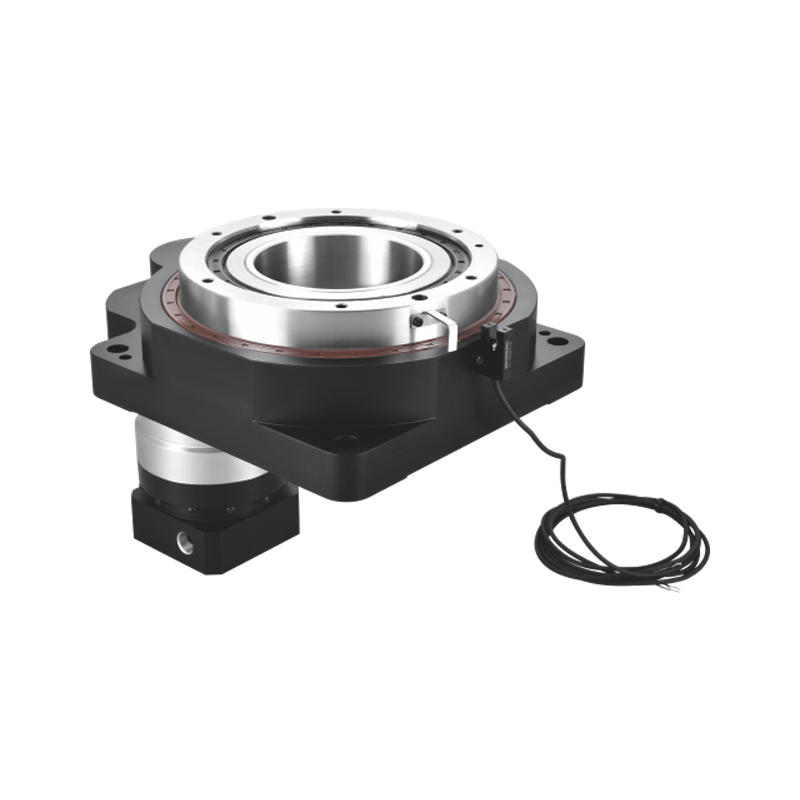

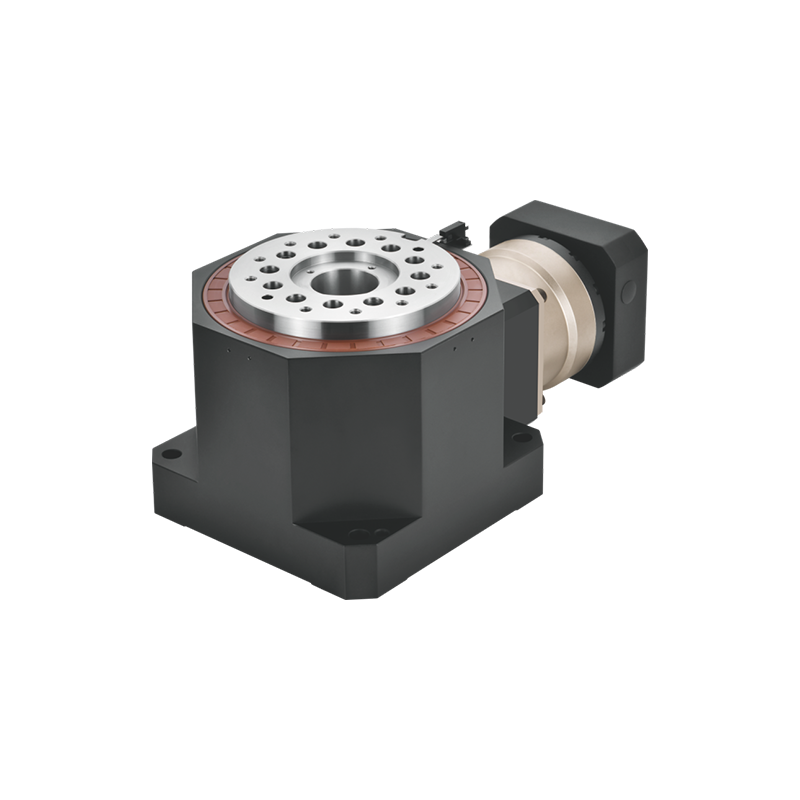

What kind of bearings are used in hollow rotating platforms?

Hollow rotating platforms usually use crossed roller bearings. The structure of this kind of bearing is very special. The bearing rollers are arranged vertically staggered inside, and the diameter of the crossed rollers is slightly larger than the diameter of the raceway. The purpose of using crossed roller bearings is to give the hollow rotating platform the ability to withstand moments from multiple directions such as axial and radial directions.

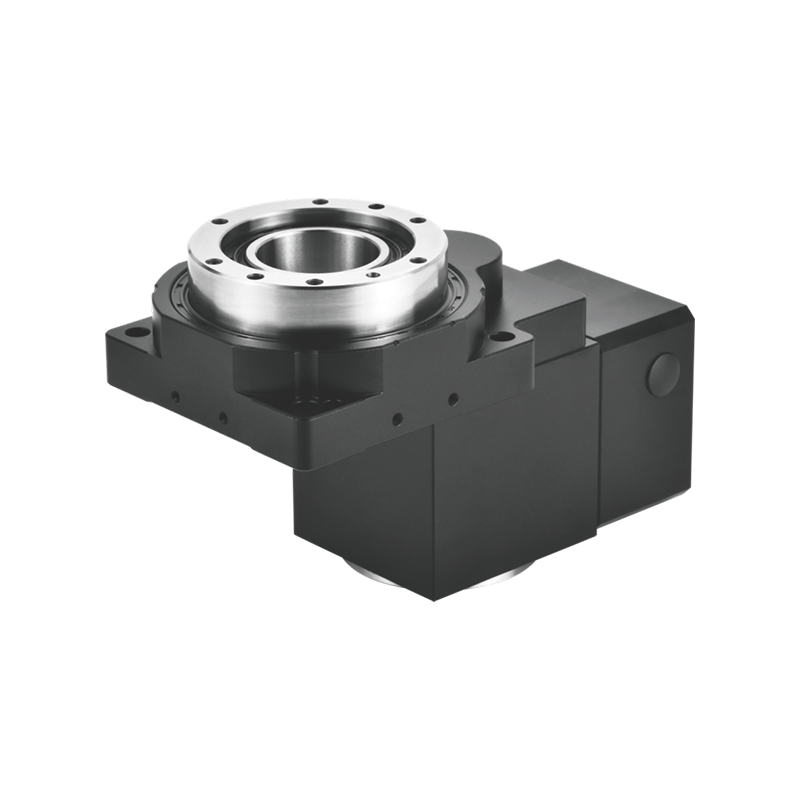

Why does the hollow rotating platform shake?

There may be many reasons for the vibration of the hollow rotating platform.

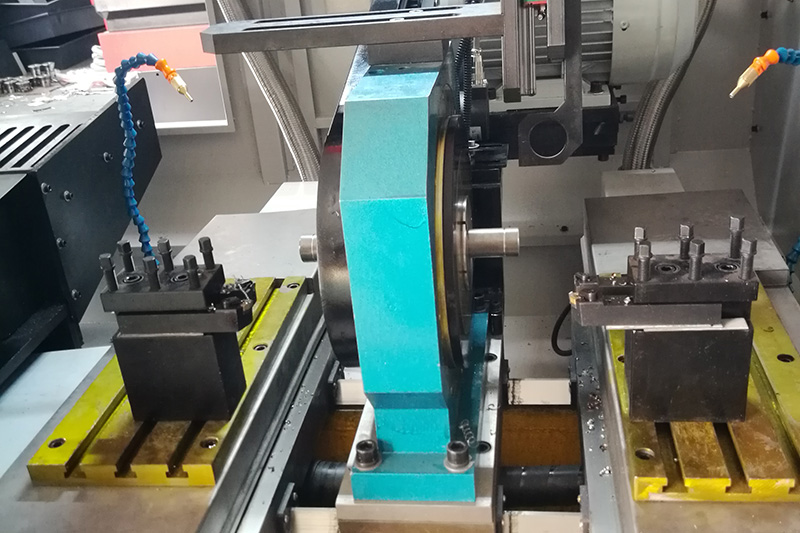

First, mechanical component failure can cause judder. For example, problems such as bearing damage and gear wear may affect the stability of the platform during operation, resulting in jitter. In addition, the additional load borne by the hollow rotating platform may also cause vibration. Common reasons include uneven lead screw pitch, uneven worm splitting, substandard quality of plane pressure bearings and tapered bearings, and the upper and lower sheaths of the lead screw are too tight. There are also problems such as inconsistent installation.

Alternatively, the jitter may be caused by a problem with the reducer. For example, the noise produced by the reducer during use may be due to the unbalanced splitting of the multi-head worm of the fast planetary reducer, or the noise at slow speeds may be due to bearing quality problems. These problems may affect the normal operation of the reducer and cause jitter.

In addition, if the reducer is overheated or stuck, it will also cause vibration. Usually the normal working temperature of the reducer should not exceed 45 degrees Celsius. If it overheats, it should be shut down immediately for inspection. High temperature may be caused by overload caused by too small selection of reducer, or high temperature caused by too tight worm and worm gear end cover. Too fast input speed may also cause high temperature and jamming.

What kind of bearings are used in the hollow rotating platform and why the hollow rotating platform vibrates?

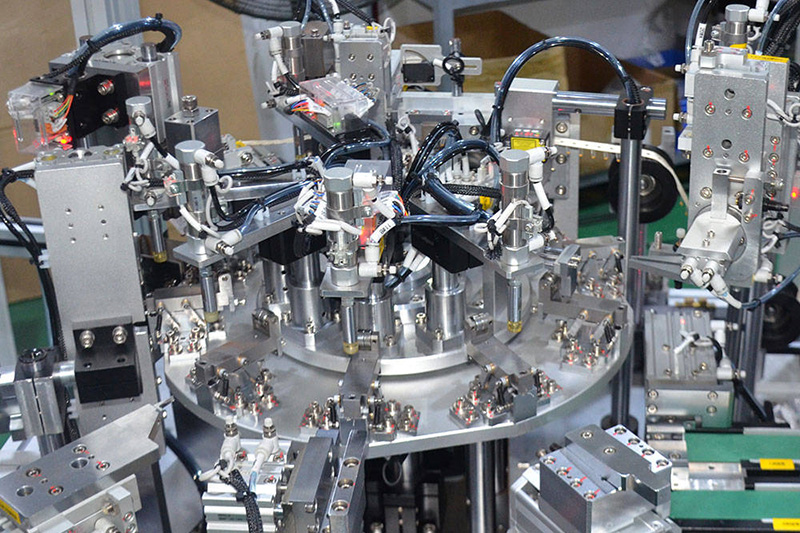

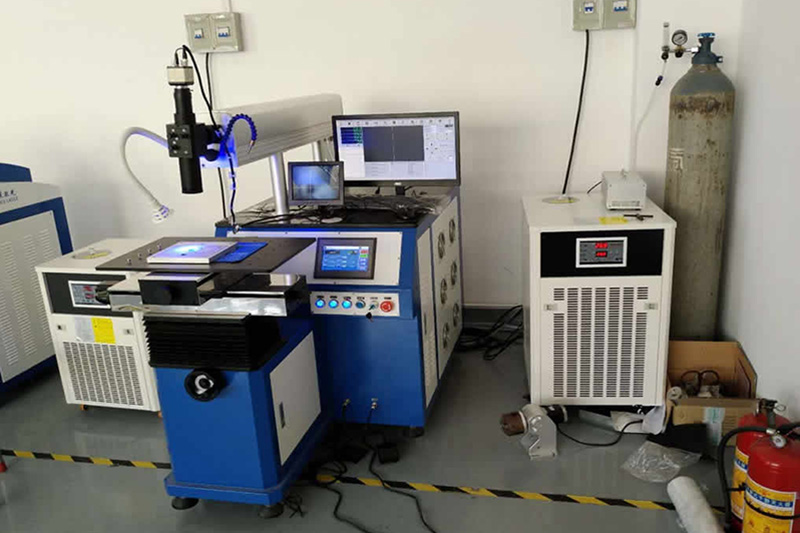

As a manufacturer, Zhuoerchuang always adheres to the principle of quality first and customer first, and continuously improves product quality and service levels based on modern science and technology and scientific management methods. We have high-level manufacturing equipment and an excellent team of technicians, and have high-efficiency, high-quality production capabilities. We firmly believe that only as a manufacturer can we truly strictly control every detail and ensure that every product meets or exceeds customer expectations and needs. Zhuoerchuang mainly supplies hollow rotating platform reducers and hollow rotating platforms from stock.