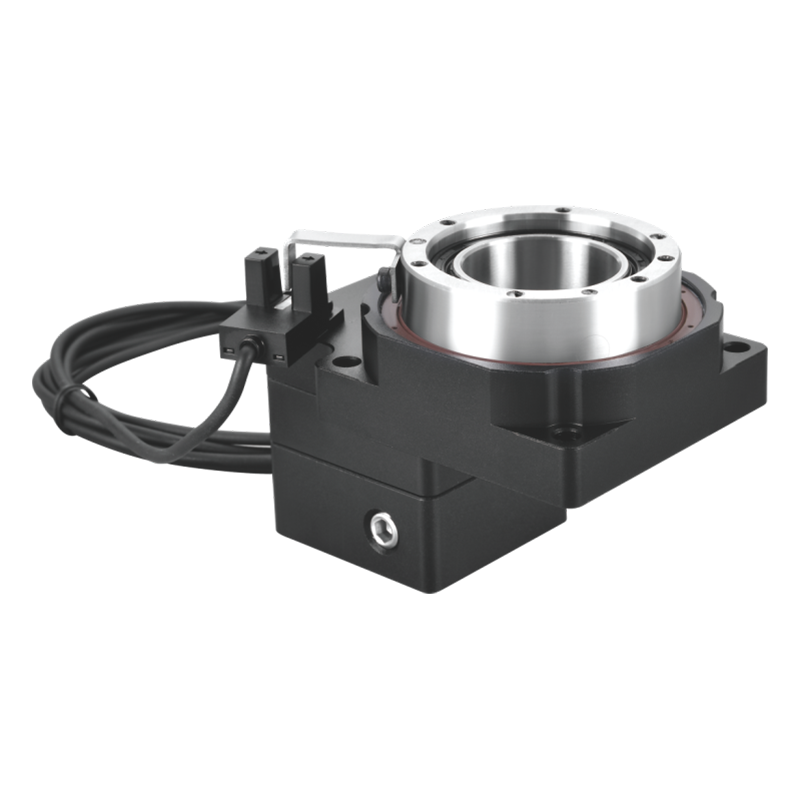

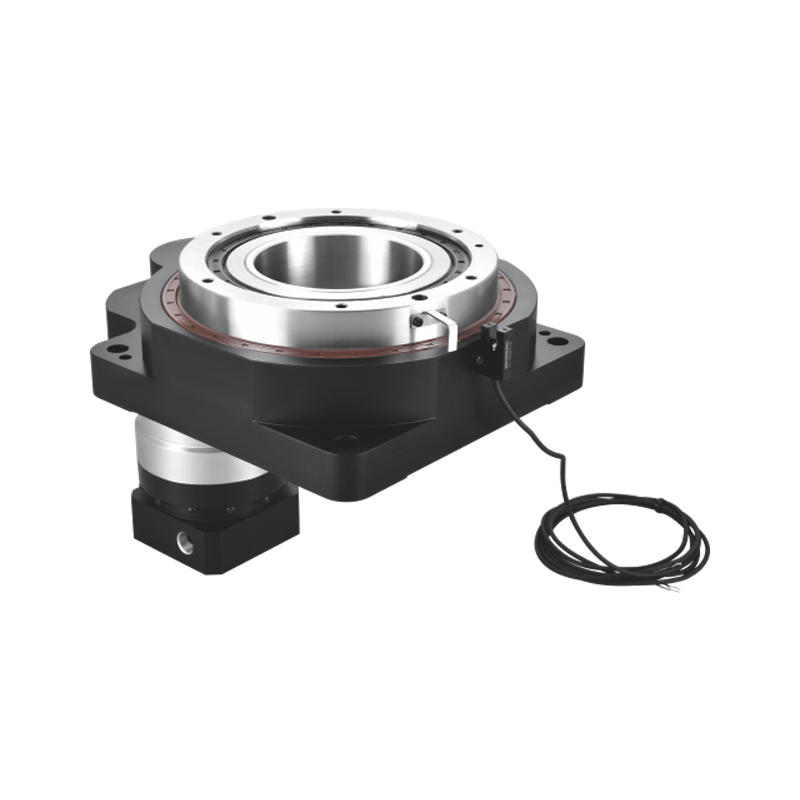

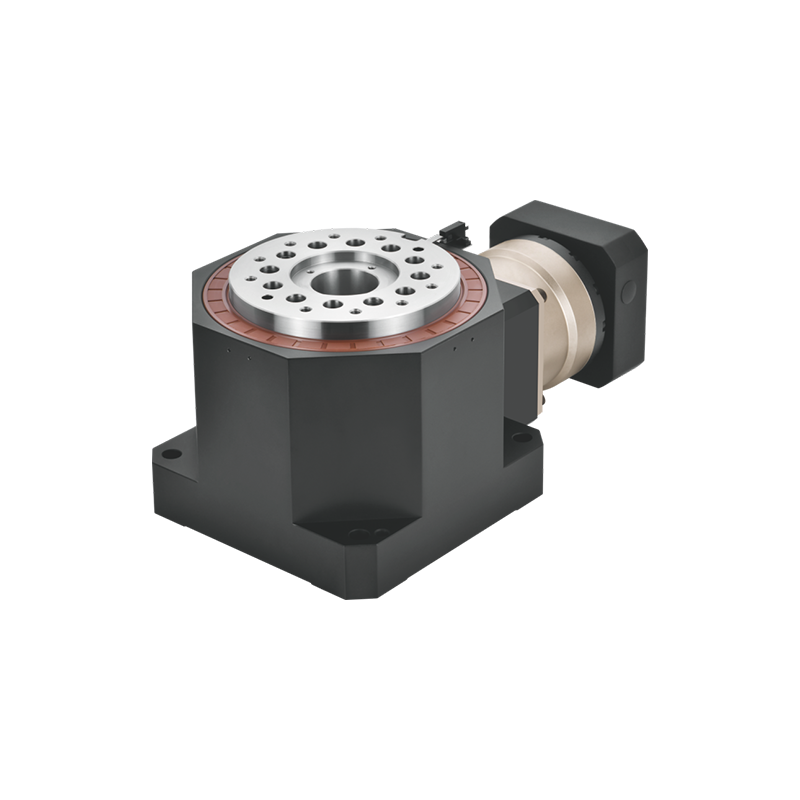

Hollow rotating platform

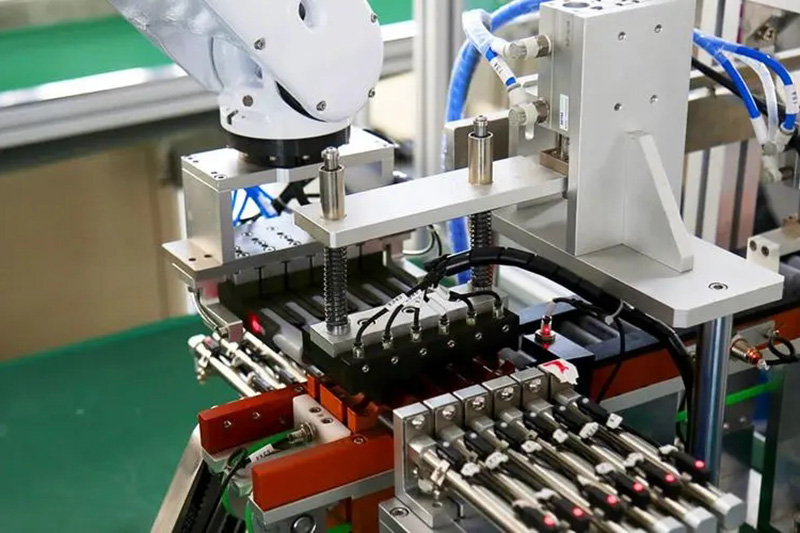

The hollow rotating platform is a rotating motion control device with high precision, high rigidity and high speed. Its interior adopts an integrated casting process and has high strength and rigidity. At the same time, it also has a hollow structure, which can be conveniently installed with various sensors and actuators to realize automatic control.

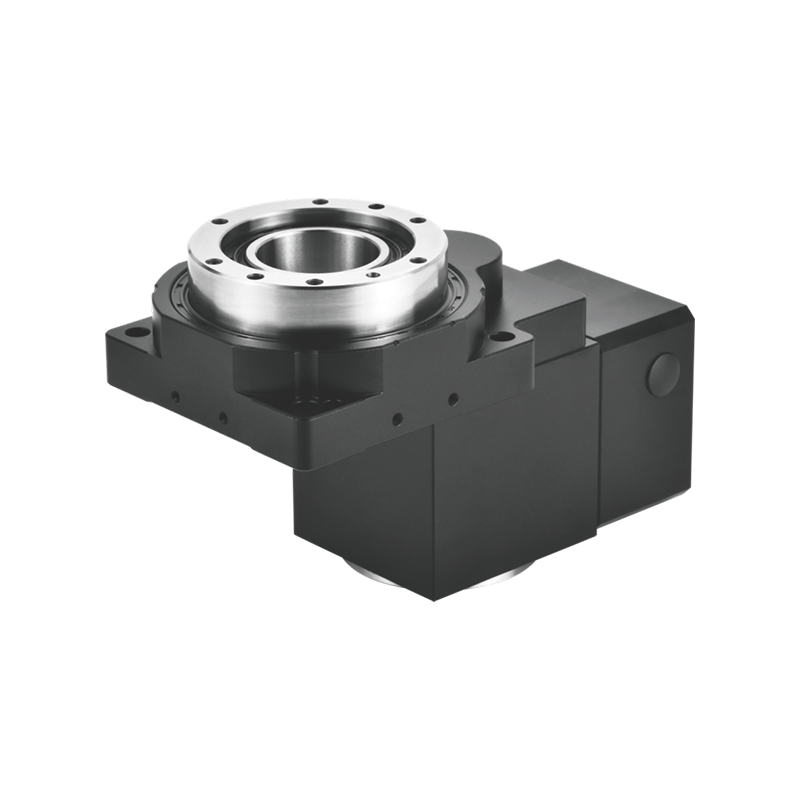

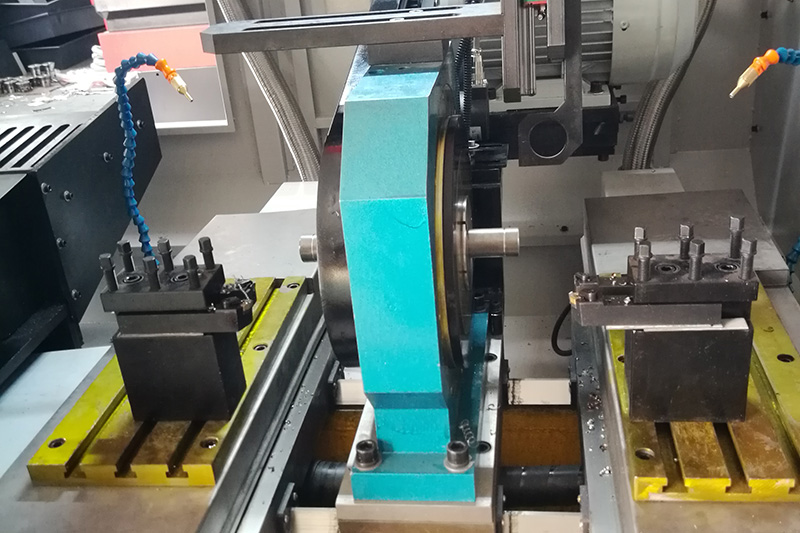

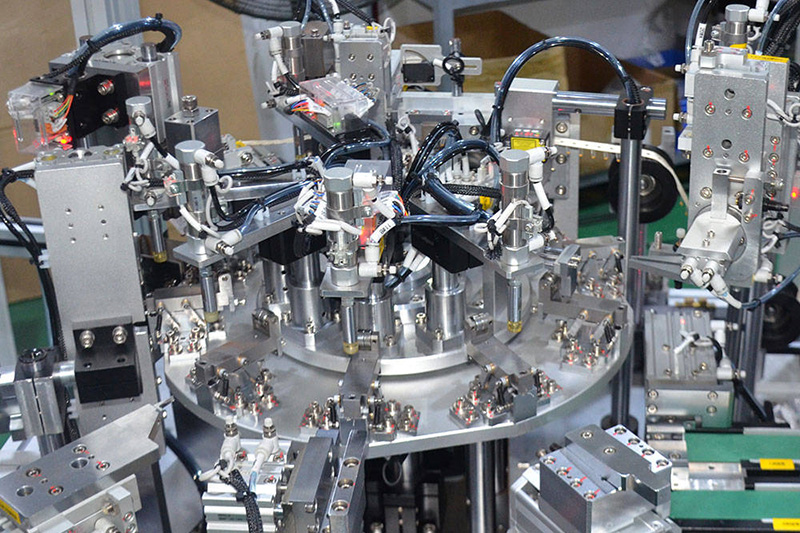

cam splitter

The cam divider is a mechanical device used to divide motion. It has a set of cams and rollers inside. By adjusting the position of the cam, the starting position, rotation angle, motion period and other parameters of the output shaft can be controlled. The cam splitter has the advantages of high precision, long life and simple structure, and is widely used in automation equipment, robots and other fields.

The difference between hollow rotating platform and cam divider

Hollow rotary table and cam divider are two different motion control devices, and their application scenarios and functions are also different. The hollow rotary platform is more suitable for high-precision and high-rigidity rotary motion, while the cam divider is more suitable for precise split motion. In practical applications, suitable motion control elements can be selected according to specific needs.

Zhuoerchuang hollow rotating platform reducer has the following advantages:

1. Direct installation: The hollow rotating platform can be directly connected to various equipment without using mechanical parts such as pulleys, thus reducing the time and cost of mechanical design, parts equipment, strip scheduling and other aspects.

2. Optional equipment: The hollow rotating platform can freely select drive motors, including servo motors and stepper motors, to adapt to different application scenarios.

Gearless height positioning: The hollow rotating platform uses a single-stage helical gear reduction to increase output torque, achieving gap-free, high positioning accuracy and smooth operation.

3. Easy to maintain: The turntable of the hollow rotating platform is a hollow structure, which facilitates wiring, piping and other operations, and reduces the difficulty of maintenance.

4. High-precision control: The hollow rotating platform adopts high-precision gear structure and radial bearings, which has high repeatability positioning accuracy and low backlash characteristics, and can achieve precise control.

5. Space saving: The middle of the hollow rotating platform is hollow, which can easily install various sensors, actuators and other devices. At the same time, its structure is compact and does not take up too much space.

6. Various installation methods: The hollow rotating platform can be installed in various installation methods such as side mounting, hoisting, flat mounting, and vertical mounting to adapt to different application scenarios.

To sum up, Zhuoerchuang hollow rotating platform has significant advantages in direct installation, arbitrary equipment, gearless height positioning, easy maintenance, high-precision control, space saving and multiple installation methods, making it popular in the automation industry. Wide range of applications.