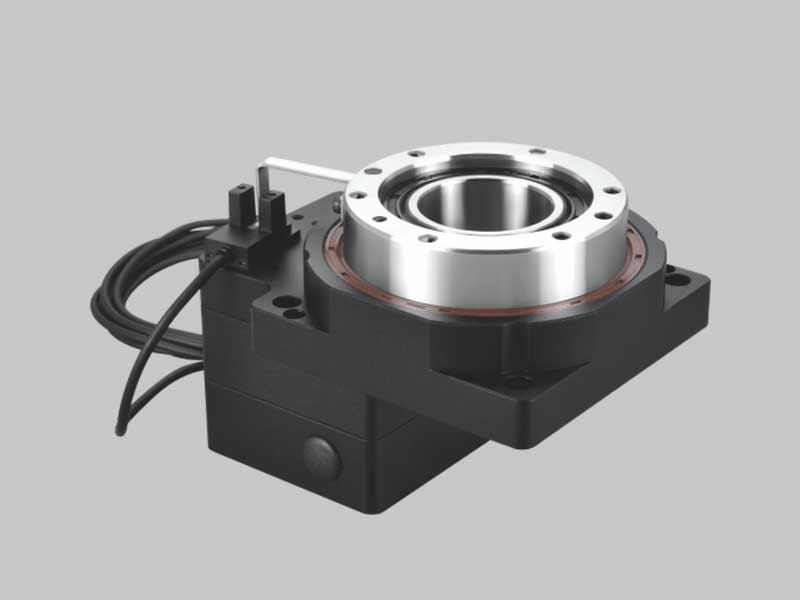

The selection requirements for servo hollow rotating platforms can be summarized as follows:

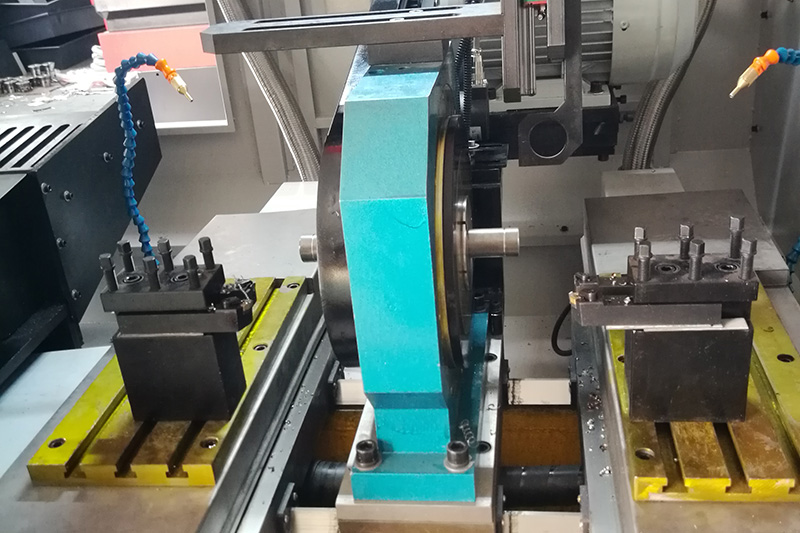

1. Platform load: According to the actual application requirements, select a hollow rotating platform that can bear the load size.

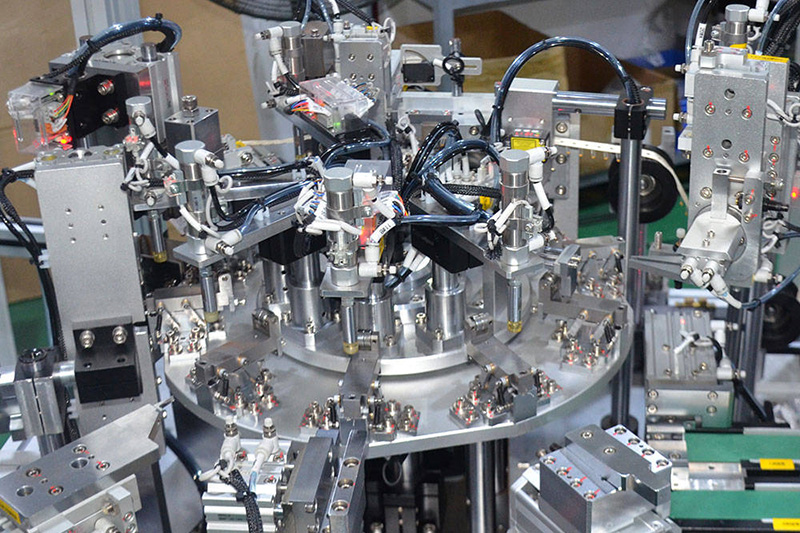

2. Turntable diameter: Find a hollow rotating platform with a suitable diameter based on the actual size of the objects that need to be rotated.

3. Rotation speed: According to the actual rotation speed, the hollow rotating platform with a reasonable speed is selected.

4. Use environment: Choose the use environment, such as ambient temperature, ambient humidity, mechanical vibration, etc., and choose a hollow rotating platform suitable for these environmental conditions.

5. Accuracy requirements: According to the actual rotation accuracy requirements, select a hollow rotating platform with appropriate accuracy.

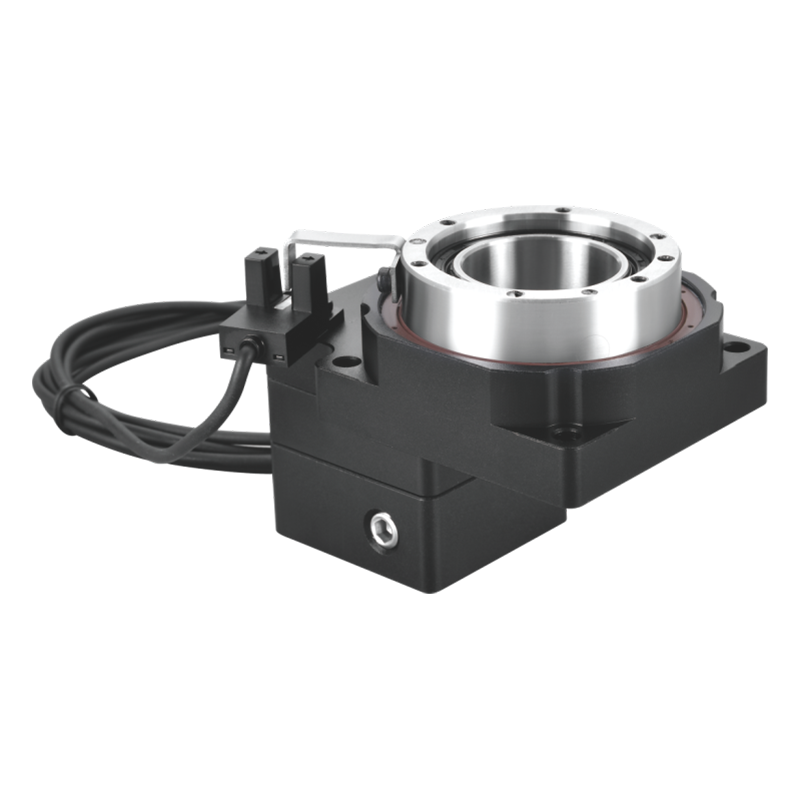

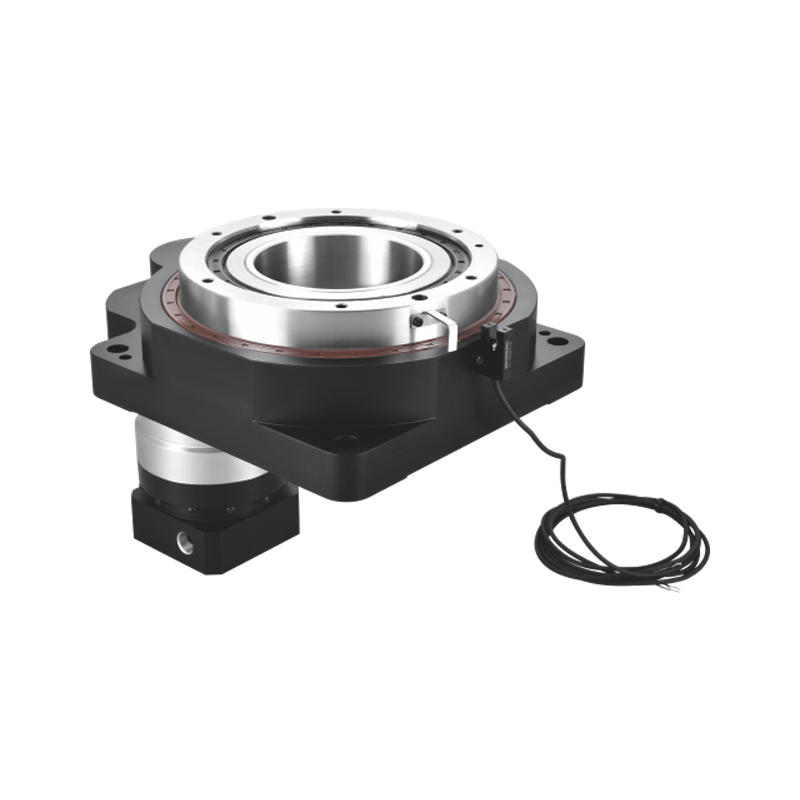

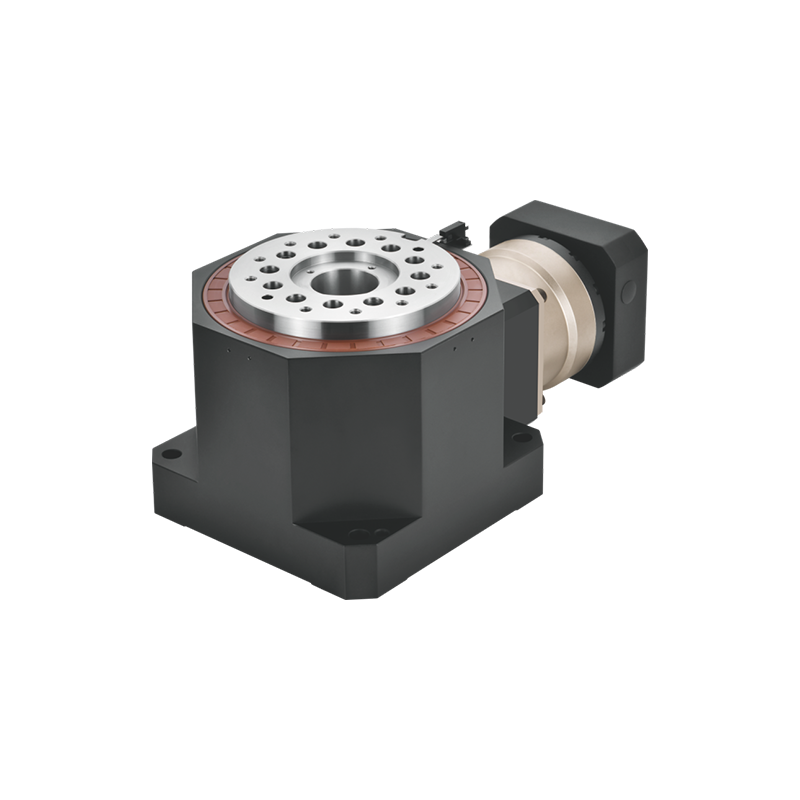

6. Hollow structure: If it is necessary to install air pipes, wires, etc. on a rotating platform, a hollow rotating platform with a hollow structure should be selected, which can facilitate the installation and use of air pipes and wires.

7. High-precision positioning: Select a hollow rotating platform with high repeat positioning accuracy, small return clearance, and small dynamic backlash difference to ensure the accuracy and stability of the rotating platform.

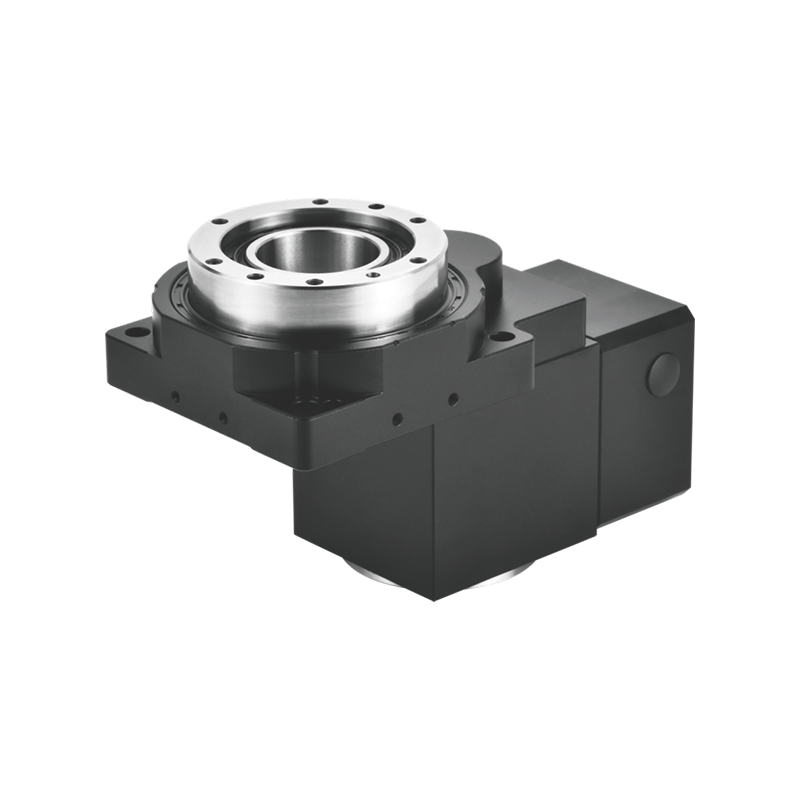

8. High rigidity/high torque: Select a hollow rotating platform with high rigidity and high torque to ensure the stability and rotation accuracy of the rotating platform when it is subjected to load.

9. Noise reduction design: If it is necessary to reduce the noise of the rotating platform, a hollow rotating platform with customized noise reduction should be selected.

10. High efficiency: Select a high-efficiency hollow rotating platform to ensure high-precision control with relatively low energy consumption.

11. Elastic motor connection: Select the connection between the input end and the motor to use a collet-type locking mechanism, and undergo dynamic balance analysis to ensure the concentricity and balance of the joint interface under the input speed, as well as zero backlash power transmission.

12. Bearing selection: Based on actual needs, reasonably select bearing types and sizes to support the stable operation of the rotating platform.

13. Helical gear design: If it is necessary to achieve the characteristics of low noise, high output torque and low backlash, a hollow rotating platform customized with helical gears should be selected.

14. Direct connection: If it is necessary to directly lock the rotating platform with the load, a hollow rotating platform with direct connection function should be selected.

Generally speaking, when selecting a servo hollow rotating platform, it is necessary to comprehensively consider various factors such as platform load, turntable diameter, rotation speed, use environment, accuracy requirements, etc. At the same time, attention should be paid to the hollow structure, high-precision positioning, high rigidity/high torque, and drop resistance. noise design and other key points to achieve precise, stable and efficient rotational motion control. Zhuoerchuang adheres to the business principle of "quality wins customers' respect, and innovative services give back customer trust". With the positioning of "precision machinery uses Zhuoerchuang precision reducers", it is committed to building a Chinese precision reducer brand and making unremitting efforts. Zhuoerchuang's products mainly include: hollow rotating platform reducer, Haibo tooth hollow rotating platform, etc.