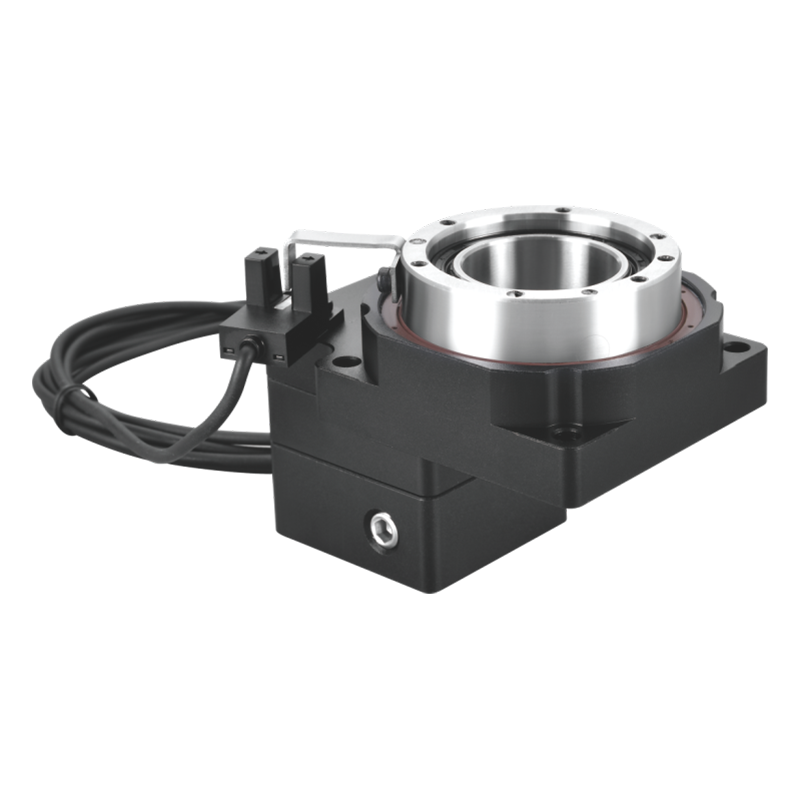

The gear is an important part of the gear reducer. For the gear reducer, the gear plays an important role. If a good gear is used, the advantages of the gear reducer are as follows:

1) High efficiency In the commonly used mechanical transmission, the gear transmission efficiency is the highest, and the closed transmission efficiency is 96%~98%, which has great economic significance for high-power transmission.

2) The compact structure is smaller than the space required for belt and chain drive.

3) Stable transmission ratio Stable transmission ratio is often the basic requirement for transmission performance. Gear transmission is widely used because of its characteristics.

4) Reliable work and long life. Designed and manufactured correctly and reasonably, using well-maintained gear drives, work is very reliable, and the life span can be as long as ten or twenty years, which is unmatched by other mechanical drives.

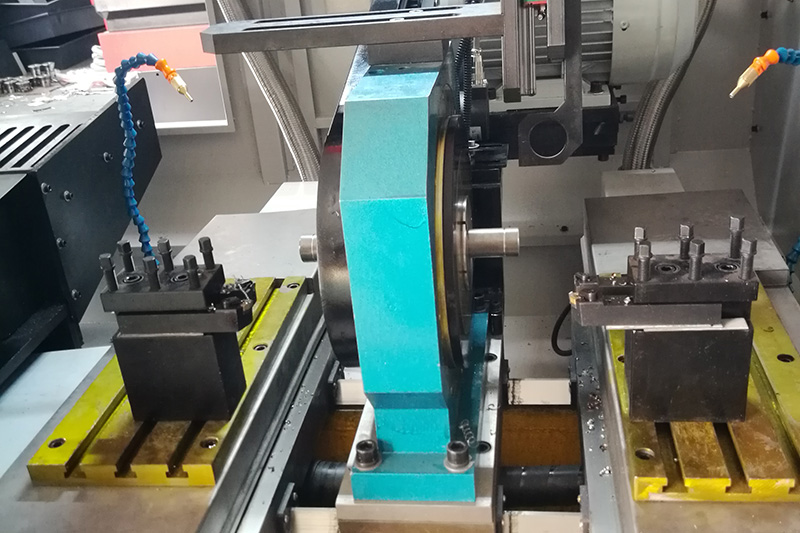

The gears that make up the gear reducer are divided into helical gears and spur gears. Why are the gears of many gear reducers inclined? We can get the reason by comparison.

1. Compared with spur gears, the position of the shaft of the helical gear reducer is more free. For example, the differential drive shaft with oblique bevel gears does not have to be on the same level as the rear axle. It is necessary if it is straight bevel gears.

2. Reduce noise. If the gear reducer uses helical teeth, the noise will be much lower than straight teeth at the same speed. The reason is that the surface of the helical teeth of the gear reducer is in point contact first, then transitions to surface contact, and finally to point contact. The spur gear is the contact between the surface and the line. The transition of helical teeth is smoother. Therefore, the noise generated by the sudden change of contact is much smaller than that of a flat tooth.

3. The helical gear has a large coincidence degree and a large number of teeth enter the mesh at the same time. Reduce impact and noise, make the transmission more stable, and can withstand high-speed heavy loads.

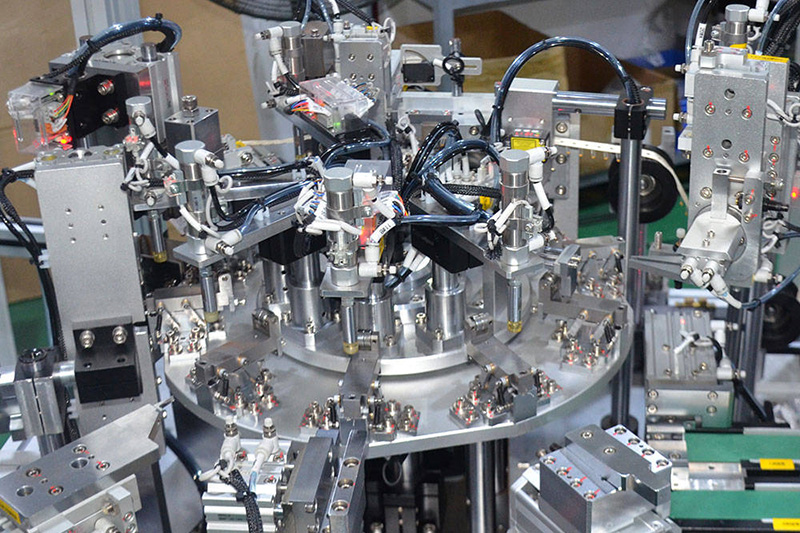

4. During the processing, the minimum number of teeth to avoid undercutting is small. Corresponding gears should be small, so when the transmission ratio of the transmission pair is the same, the volume of the gear reducer using helical gears should be small.

5. Convenient production. A set of helical gear reducers with the same face width and different face widths can be produced on the cylindrical blank with a gear hobbing machine, which can be cut into different face widths according to customer needs.

The transmission of spur gears has poor stability, high impact and noise. The gear reducer uses helical gears with large transmission overlap and good tooth surface contact, so the load capacity is high; the minimum number of teeth of helical gears is smaller than that of spur gears, so the mechanism is more It is compact and has the same manufacturing cost as a spur gear. The use of helical gears in gear reducers is more reasonable and suitable for engineering practice.

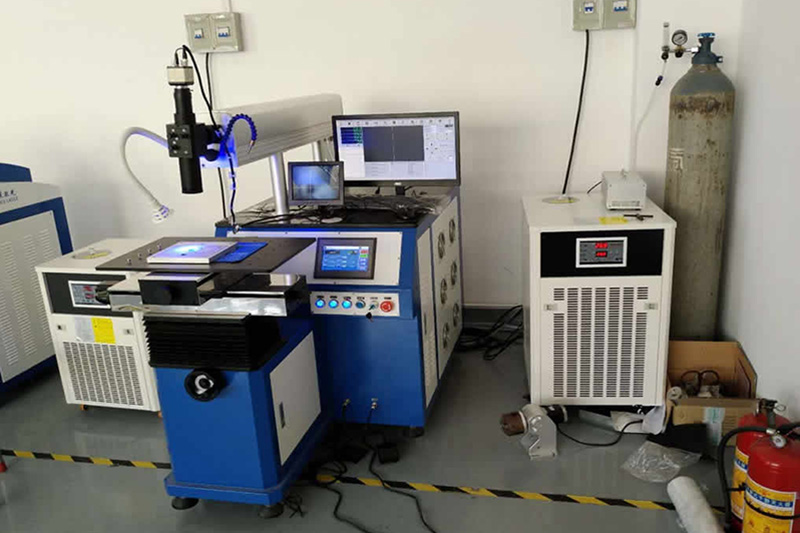

Helical gear reducer has so many advantages, but its advantages are based on precise manufacturing, superb surface treatment, and sophisticated tooth profile correction. Therefore, Precision Machinery has been working hard on technology and craftsmanship, and strive to produce more precise and exquisite gear reducers.