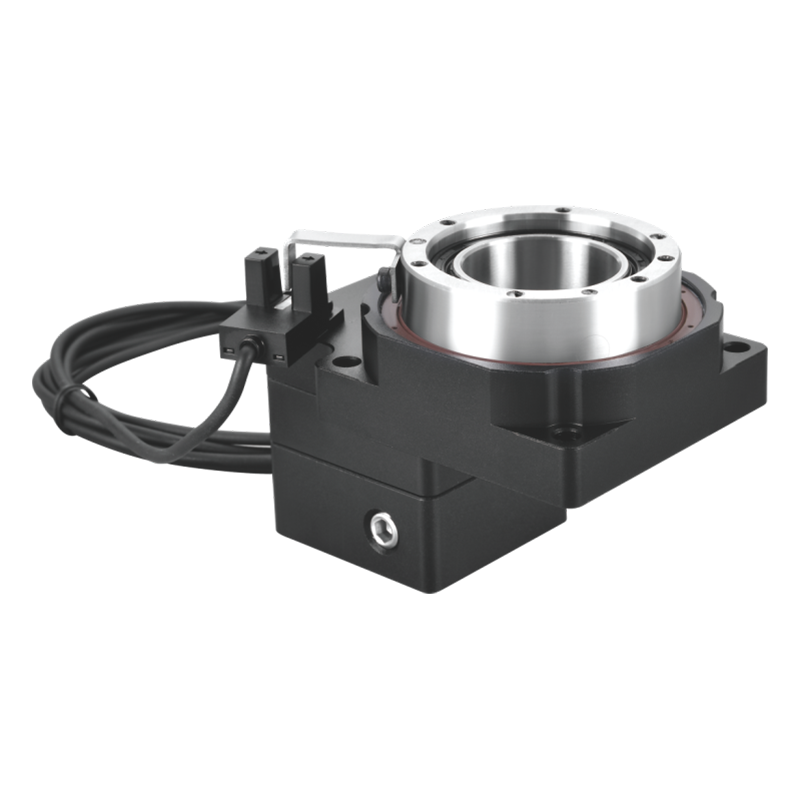

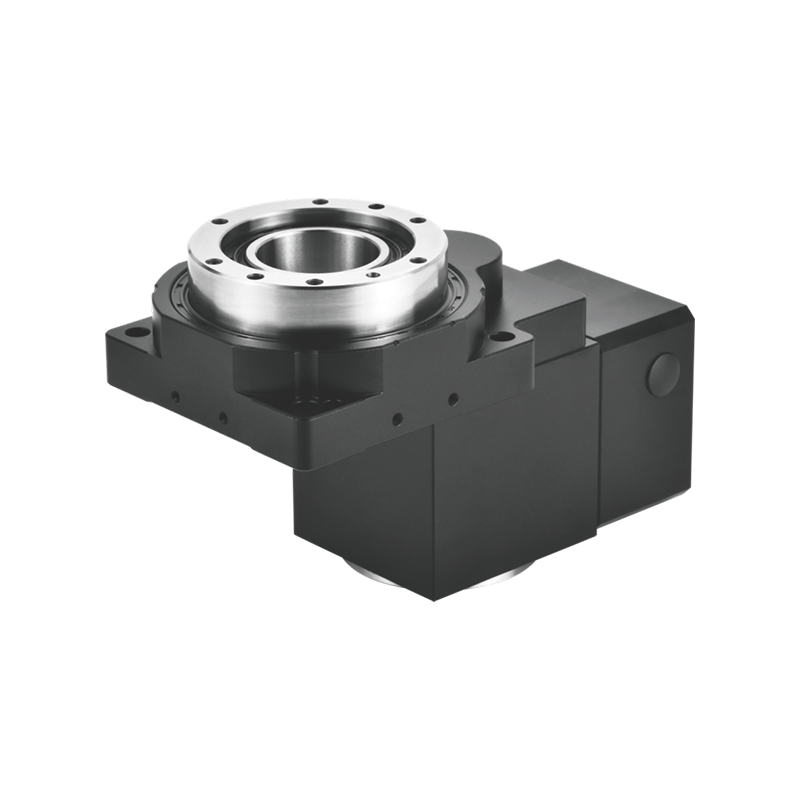

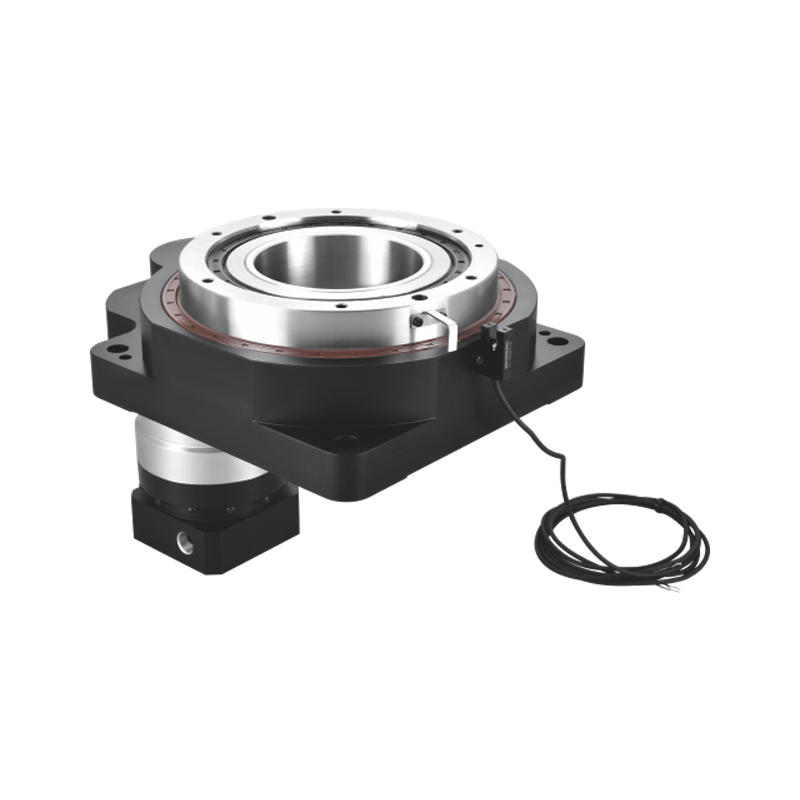

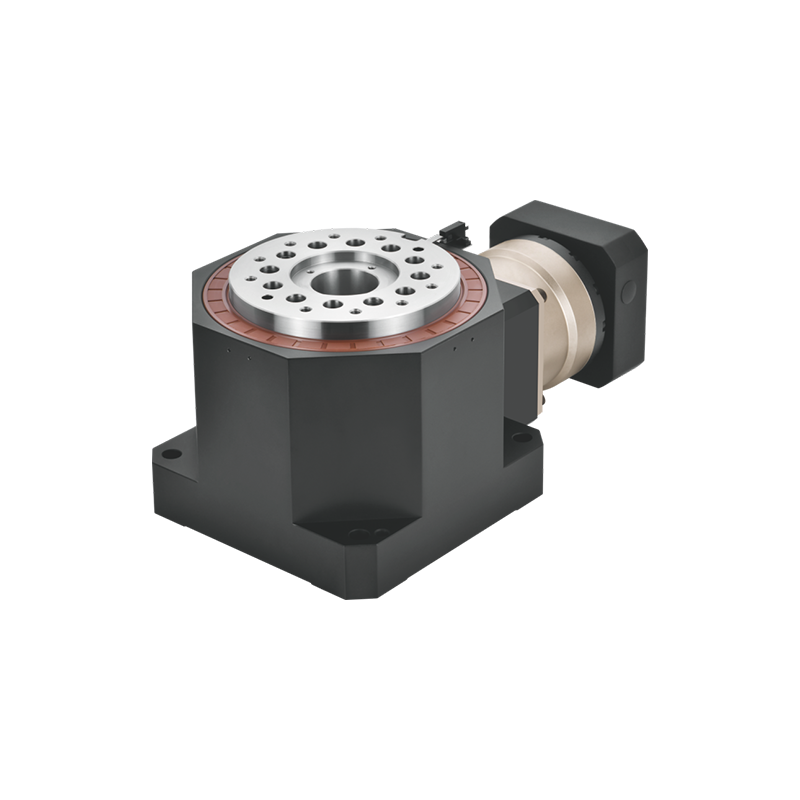

Heavy-duty hollow rotating platform selection requirements:

1. Platform load: According to the actual load required, select a heavy-duty hollow rotating platform with good load. Factors such as the load-bearing capacity, rotation speed, and radius of rotation of the rotating platform must be fully considered to ensure that the platform can withstand various loads in actual work.

2. Turntable diameter: Select a heavy-duty hollow rotating platform with a good diameter based on the actual size of the object to be rotated. The diameter of the turntable will affect parameters such as rotation speed, rotation radius, load size, etc. The appropriate diameter should be selected according to actual needs.

3. Rotation speed: According to the actual rotation speed, select a heavy-duty hollow rotating platform with good speed. Factors such as the power, load-bearing capacity, friction and other factors of the rotating platform must be fully considered to ensure that the rotation speed will not adversely affect the working performance of the platform.

4. Usage environment: Consider the usage environment, such as temperature, humidity, vibration, etc., and select a heavy-duty hollow rotating platform with appropriate environmental adaptability. A suitable rotating platform should be selected according to the actual working environment to ensure the stability and safety of the work.

5. Accuracy requirements: According to the actual rotation accuracy requirements, select a high-precision heavy-duty hollow rotating platform. Accuracy requirements include rotation angle, positioning accuracy, repeatability, etc. A rotating platform that meets the accuracy requirements should be selected based on actual needs.

6. Bearings and shafting: It is necessary to consider the configuration and performance of bearings and shafting, and select a hollow rotating platform that meets heavy-load working conditions. Factors such as bearing capacity, wear resistance, and fatigue resistance must be fully considered, as well as factors such as the stability, rigidity, and accuracy of the shaft system.

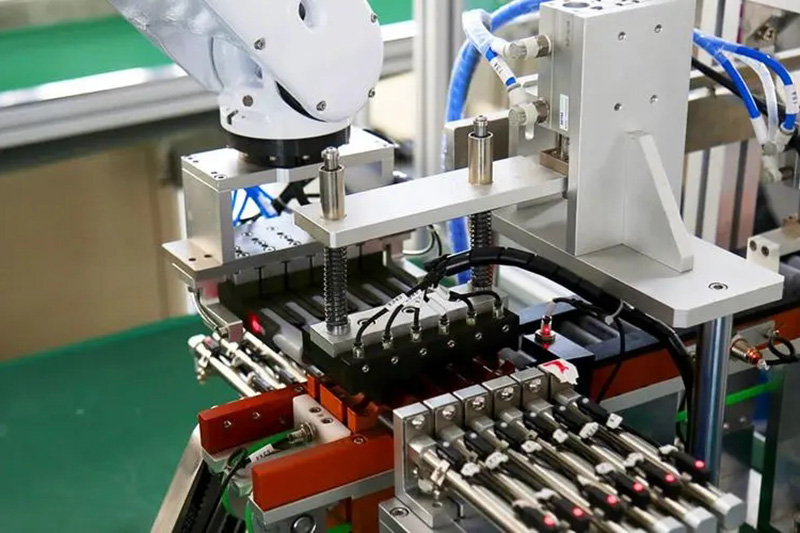

7. Drive system: It is necessary to consider the configuration and performance of the drive system and select a hollow rotating platform that meets the heavy-load working conditions. Factors such as the power, torque, and stability of the drive system, as well as factors such as matching with the rotating platform, must be fully considered.

In short, when selecting a heavy-duty hollow rotating platform, you should comprehensively consider the actual application needs and working conditions, select a hollow rotating platform that meets the conditions, and strictly abide by the corresponding operating procedures and precautions to ensure the stability and stability of the rotating platform. safety. Shenzhen Zhuoerchuang always adheres to high quality standards and has passed ISO9001:2000 international quality management system certification to provide better quality products. Each product undergoes strict quality control before leaving the factory. We are committed to giving every customer and friend more peace of mind and higher quality products. Zhuoerchuang mainly supplies hollow rotating platform reducers and hollow rotating platforms from stock.